The very first lathes were listed as being powered by a 7.5 hp (5.6 kW) motor but this proved to be inadequate and much a more powerful 12.5 hp (9.3 kW) unit was soon made standard The motor was mounted inside the headstock-end plinth on an adjustable plate and drove up to the headstock through 4 V belts into a shaft on which were mounted two easily-adjusted, oil-immersed, forward and reversing clutches.

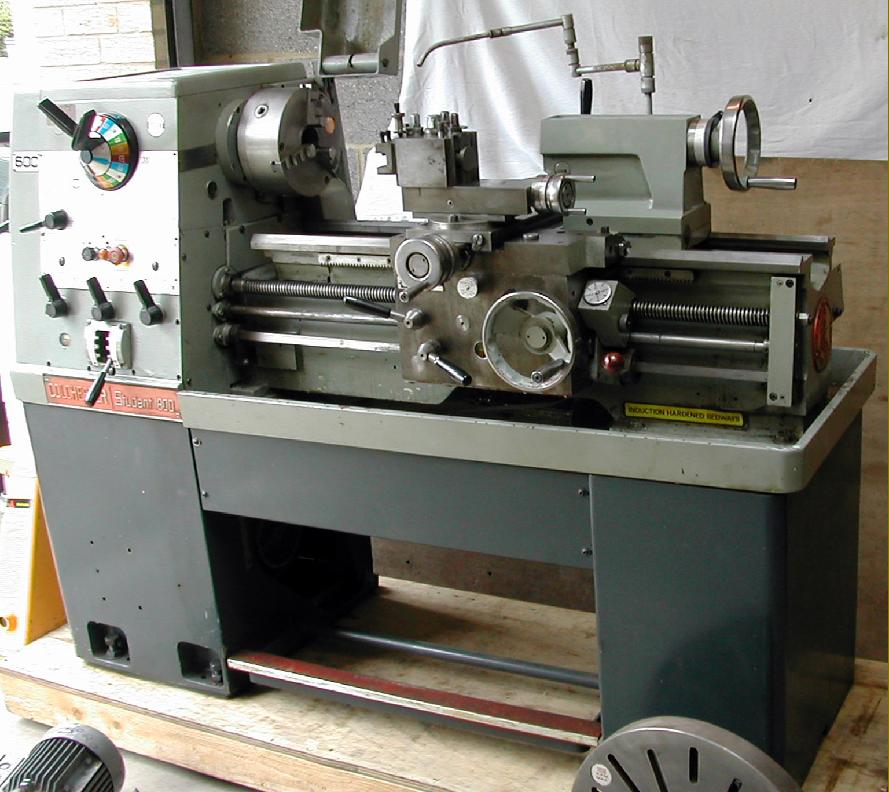

You are welcome to email for advice as to what might be suitable, Concentrically mounted paddle levers on the front face of the headstock selected the spindle speeds and worked through an ingenious and compact mechanism, with (for a machine tool) an almost foolproof system of colour coding to indicate the settings.

Colchester triumph 2000 lathe parts manual manual#

colchester mascot 1600 lathe manual pdf, colchester mascot 1600 lathe specifications, colchester mascot 1600 lathe parts, colchester mascot 1600 lathe manual, colchester mascot 1600 lathe manual for sale, colchester mascot 1600 lathe manual free, colchester mascot 1600 lathe manual download.ġ6 speeds were available, from 20 to 1600 rpm and, because of the high top speed and the capacity of the lathe, the makers warned against other than the use of the dynamically balanced, ductile-iron chucks with hardened scrolls that had been specially commissioned from Burnerd if you want to mount a new chuck on your Mascot 1600 it would be unwise to fit anything other than one recommended by a reputable Western manufacturer.Designed in conjunction with the British Machine Tool Industry Research Association the headstock spindle could pass a 3-inch diameter bar and had a hardened 8-in D1 Camlock nose all the gears in the headstock (and not just those responsible for the main drive as on less heavily stressed Colchester models) were hardened and ground finished on Reishauer machines. Because it sat on a flat section of the bed instead of a continuation of the V ways, the headstock was provided with a mechanism that allowed it to be adjusted laterally - though before altering the factory setting the owner was strongly cautioned to consult the (very comprehensive) owner's manual. All the beds could be had either with or without a detachable gap piece that, if fitted, allowed material up to 28-inches (711 mm) in diameter and 8.5 inches (216 mm) thick to be swung on the (optional-extra) 17-inch and 27-inch (433 mm or 685 mm) diameter faceplates. It was available in four lengths that gave 40, 60, inches (1000 mm, 1500 mm, 2000 mm and 2500 mm) between centres. Induction hardened and ground-finished as standard, the bed was 13.5 inches (343 mm) wide and of the usual Colchester V-and-flat type, with separate pairs of ways for the carriage and tailstock. It would be unfair, however, to dismiss the Mascot 1600 as a mere styling exercise for this lathe was sold in an important and profitable (though demanding) section of the market - and to succeed it needed to be tough, well-made, reliable and with a combination of capacity, speed and ease of use that backed up its contemporary appearance. PDF, ePub, eBook, fb2, mobi, txt, doc, rtf, djvu ▶▷▶▷ colchester mascot 1600 lathe manual colchester mascot 1600 lathe manual File Name:

0 kommentar(er)

0 kommentar(er)